How to Weld Quarter Turn Dzus Tabs onto Roll Cage Tubing

Share

Whether you're mounting aluminum body panels, interior tins, or custom access doors, Dzus tabs are a racecar fabricator’s best friend. They're small, lightweight, and when installed properly, allow for fast panel removal and solid retention. But welding Dzus tabs to round roll cage tubing can be a bit tricky—especially when you're trying to get them positioned just right.

Here’s a step-by-step guide to get it done right the first time.

🔧 Tools & Materials You’ll Need

- Dzus tabs (steel or aluminum, depending on your setup)

- Dzus buttons and springs (matched to tab size)

- Roll cage tubing (typically 1.250", 1.500", or 1.625" DOM or chromoly)

- Chassis Speed Jig or Dzus tab locator (optional but highly recommended)

- MIG or TIG welder (depending on your tab/tube material)

- Angle grinder with flap disc

- Center punch and hammer

- Clamps or magnets

- Safety gear (gloves, helmet, jacket)

Step 1: Prep the Tubing

Start by cleaning the section of tubing where your Dzus tab will mount. Use a flap disc or wire wheel to remove paint, rust, or mill scale. You want shiny, bare metal for a solid weld.

👉 Pro Tip: If you're mounting to chromoly, use acetone to clean the area thoroughly—it's sensitive to contamination.

Step 2: Fit the Tab to the Tube

Dzus tabs are flat, but roll cage tubing is curved. That means you’ll either:

- Grind a saddle into the back of the tab to match the tube diameter, or

- Use a pre-cut tab with a tube-specific curve (huge time-saver)

Line it up where you want it and check that the tab lays flush. A poor fit means a weak weld.

Step 3: Use a Jig or Fixture

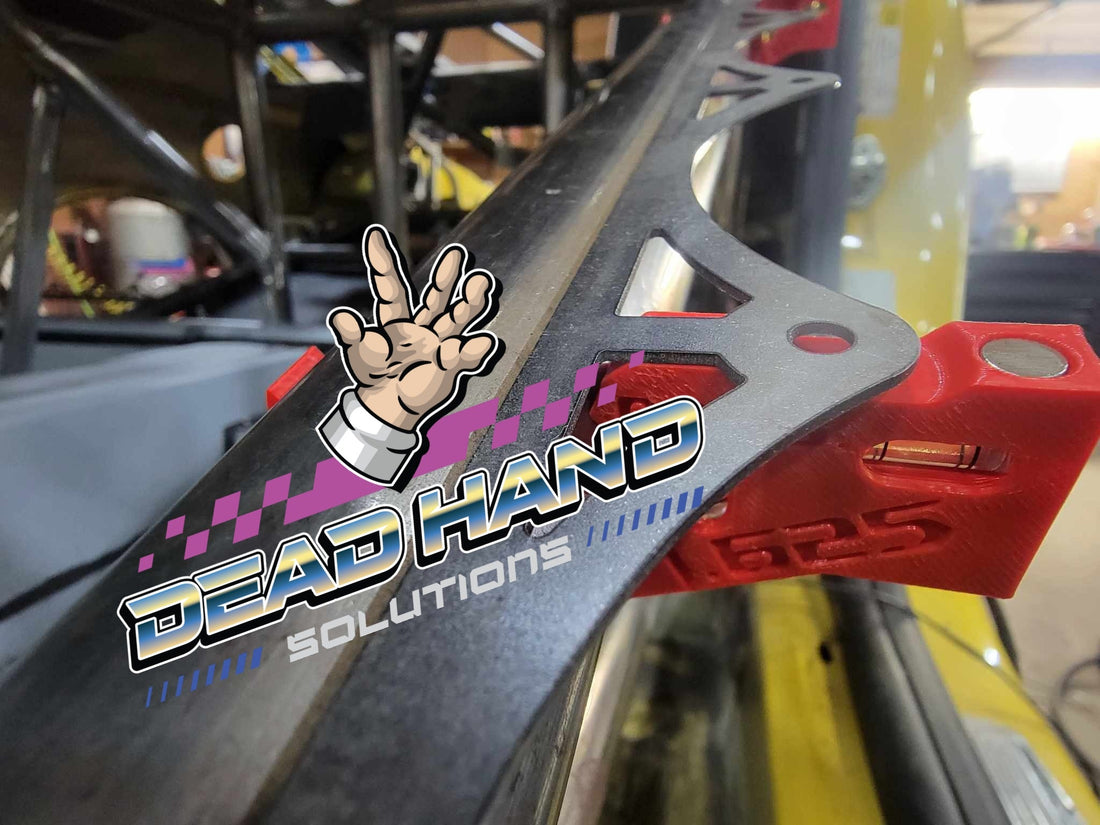

Holding a Dzus tab in place while tacking is like threading a needle with oven mitts—unless you're using a Speed Jig. A jig like the Dead Hand Solutions Chassis Speed Jig can clip onto your tubing and hold the tab in perfect position, hands-free.

- No more tape, magnets, or guessing.

- Perfect alignment every time—horizontal, vertical, even upside down.

If you're not using a jig, at least use clamps and a center punch to make sure the hole placement is accurate.

Step 4: Tack Weld

With your tab in place:

- Set your welder for thin gauge material (typically 0.060"–0.125").

- Tack both sides of the tab with quick, clean tacks.

- Check alignment again before fully welding.

👉 If your tab warps during tacking, stop and refit before continuing.

Step 5: Fully Weld the Tab

Once it’s tacked and aligned:

- Weld all the way around, or just stitch weld depending on your spec.

- Avoid overheating thin tabs—they’ll warp fast and lose strength.

- If you’re TIG welding, aim for a consistent bead with low amperage.

If you’re doing a lot of tabs, take your time and avoid stacking heat into one area.

Step 6: Test Fit Your Panels

Before moving on, always test fit the Dzus button and spring with your panel. Make sure:

- The tab hole lines up with the spring hole

- The panel sits flush with the tubing

- The button has proper tension and clicks securely

Small tweaks now save big headaches later.

Final Thoughts

Installing Dzus tabs is one of those tasks that separates a clean chassis build from a hacked-together mess. With the right prep, a jig for precision, and some patience, you’ll get tabs that look sharp and perform even better.

If you're doing more than a few, consider investing in a tool like the Chassis Speed Jig—especially if you're working one-handed or solo. It'll save you time, sanity, and give you perfect repeatable results.

Need Dzus tab jigs or precision fab tools?

Check out DeadHandSolutions.com for game-changing tools built by fabricators, for fabricators.